Industrijska Avtomatizacija

DAX FI-ROBO

Fi

- residual switches or ground fault switches are used in many applications.

Reliable FI switch operation is crucial and most demanding quality standards

are applied. DAX designed completely new approach, which provides magnetic calibration,

HV testing, all measurements according to IEC and more, ink jet marking and

sophisticated, 100% data logging and traceability. Line consists of:

·

Epson

ES551ES assembly robot with SRC320 controller, 48 digital inputs, 48 outputs

·

Magnet-Physik

MPS 2125 magnetizer with tandem coil

·

DAX

FIPC2 measurement system for FI switches, 3 units

·

DAX

HV5 high voltage test system for FI switches

·

Pneumatics

and sensorics, FESTO

·

DAX

universal FI test fixtures, 4 units

·

DAX

belt feeding system and robot cage

·

Domino

A100 ink jet contactless printer

·

DAX

FI-ROBO software: 25.000

·

DAX

FIPC2 software: 5000 Pascal program lines

·

Spel

and VB guide software for robot and IO

·

Control

computer with LCD TFT, running under Win NT4.0

·

CAN

or addressable RS485 communication link between testers and main computer

Technical characteristics

·

Cycle

time 10 to 30 seconds, depends on number of tests and FI type

·

Robot

cage dimensions: 1600x1300x1700

·

Belt

feeding system, three lines, IN, Out Good, Out Bad, length 2500mm

·

Measurement

system cabinet, 19 inch rack, 550x600x1700mm

·

Traceability

100% with FI serial number referenced to log file

DAX BSH-VK

Assembly

and test line for coffee machines. Tests are based on Bosch DBUS2 communication

protocol for home appliances

DAX BSH-Tassimo

Assembly

and test line for Tassimo home appliance

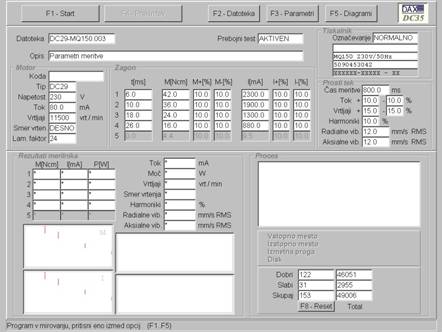

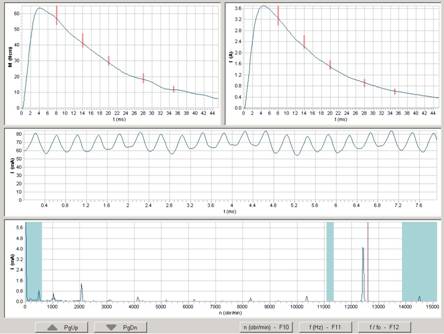

DAX FIPC2 measurement system /part

of FI-ROBO or independent unit

DAX

FIPC2 is a PC based universal instrument intended for tests on different types

of FI switches. Basically, it consists of accurate current generators, voltage,

time, conductivity and sequence circuits. User interface provides easy test

protocol editing and simple menu system.

Technical characteristics:

·

Current

ranges: 50, 100, 200, 500, 1000, 2000, 5000 and 10000mA

·

Current

shapes: sinus, + and – half wave, 5 to 135 degrees truncated sine wave, + and

-, +/- symmetrical 5 to 135 degrees truncated sine wave

·

Current

frequencies 16.66, 50, 60 and 200Hz

·

DC

offset –10 to 10mA

·

Time

measurements, Toff, 0 to 65000 micro seconds, 10 micro seconds resolution

·

Conductivity

test for N, L1, L2, L3 lines

·

Test

button check procedure with 115 and 230V

·

Switch

on sequence check (N has to switch before L1, L2, L3)

·

Free

turnoff test: turn of at fault current and pressed lever

·

Choice

of test path, N, L1, L2, L3

·

12

bit resolution

·

User

can build any sequence and number of test and store them as test data bank.

Tolerance levels and values are easily edited.

DAX-MSDC

·

Automatic

production line for small DC motors. Based on

·

Magnetizing

of assembled motors in axial coil, opening up to 70x170mm

·

Magnetic

field density of up to 1.3T

·

Magnetizer

with 1800Ws or 5000Ws energy

·

Burn

in station for three motors

·

Mechanical

and electrical tests as in DAX MDC

·

High

voltage test up to 5kV AC and 6kV DC

·

Contactless

ink jet marking with Imaje S8 or Domino A100 printer

·

Traceability

100% with motor serial number referenced to log file generated automatically.

Test results are written to control computer hard disk under serial number,

same serial number is printed on motor

·

Full

automatic operation of complete line.

·

Cycle

time 12 seconds

·

Universal

palette nests for two motor sizes

DAX NGPSP1T

Automated cable set binding and domestic appliances electronics testing. It consists of three stations, which are the final part of cable and electronics assembly line. For the first two stations, EPSON EZ robots are used for cable set binding to achieve the shortest possible cycle time. Functional tests of electronics and cables are performed at the last station, utilizing automatic manipulation and measurements.